Machine Tools

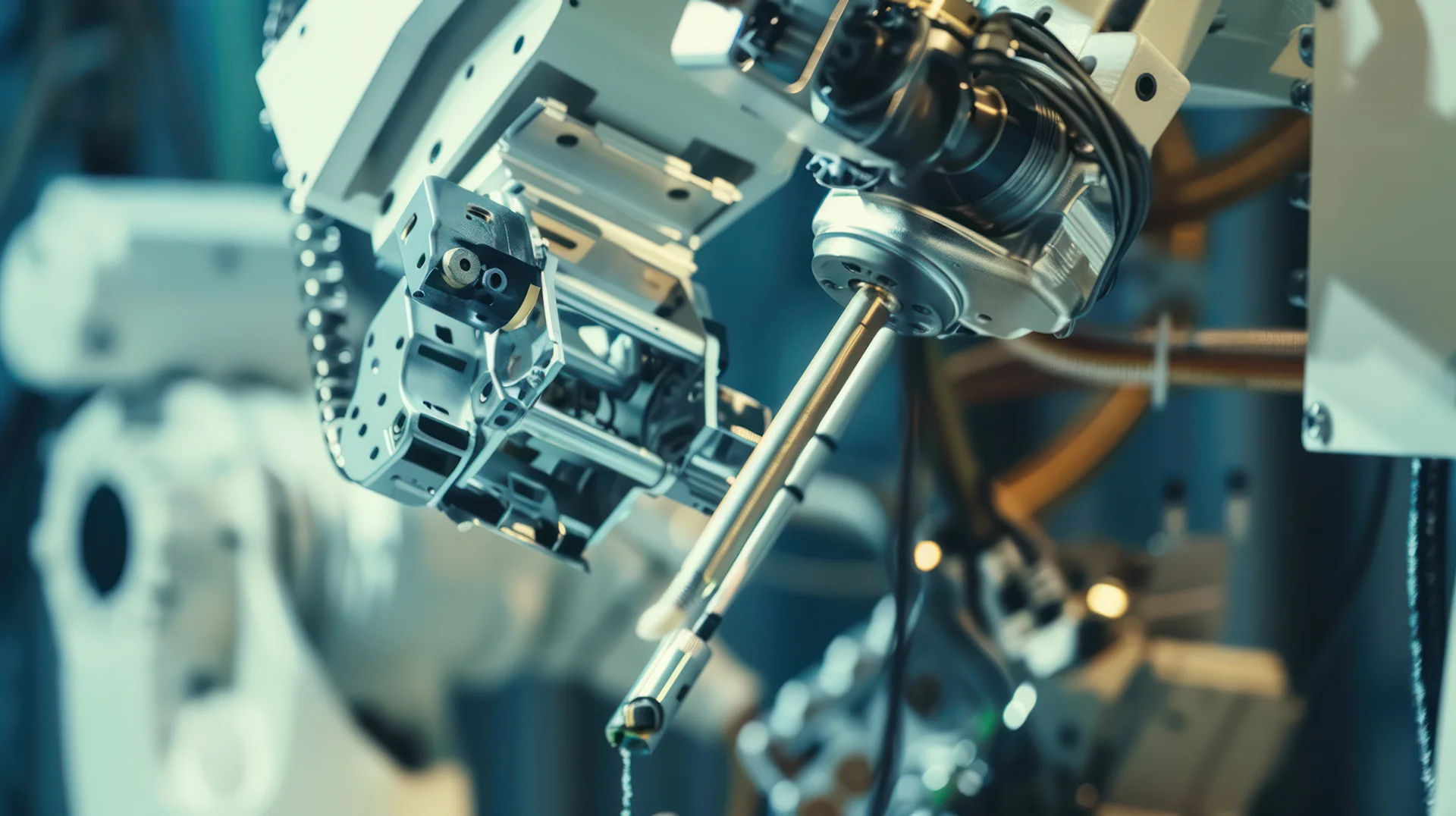

The application of sheet metal technology in the manufacturing of machine tool enclosures significantly impacts their quality. High-precision cutting and bending techniques, superior welding and surface treatments, advanced automation equipment, and flexible design and processing capabilities ensure that machine tool enclosures possess excellent strength, precision, aesthetics, and functionality. Additionally, the application of sheet metal technology enhances production efficiency, reduces costs, and meets environmental requirements. These factors collectively determine the overall quality and competitiveness of machine tool enclosures.

Besides machine tool enclosures, WeTCC also offers customized manufacturing of sheet metal enclosures for cooling machines, oil coolers, bar feeders, electric control boxes, sealing machines, and more, providing customers with the highest quality, precision, and competitive products.

Here are the main aspects of how sheet metal technology influences the quality of machine tool enclosures:

- Precision and Size Control

-

- High-precision cutting technology:Technologies like laser cutting machines can precisely cut metal sheets, ensuring the exact dimensions of each enclosure component to meet design requirements.

- Accurate bending technology:CNC bending machines can precisely control bending angles and shapes, ensuring shape consistency and dimensional accuracy of enclosure components.

- Strength and Structural Stability

-

- Superior welding technology:Laser welding robots provide high-quality welds, ensuring robust connections and structural stability and strength of the enclosures.

- Correct material selection and treatment:Choosing appropriate metal materials and applying proper heat and surface treatments can extend the durability and impact resistance of the enclosures.

- Surface Quality and Aesthetics

-

- Polishing and sandblasting treatments:These processes can make metal surfaces smooth and flat, removing oxidation layers and impurities, thereby enhancing the appearance quality.

- Painting and surface coatings:Proper coatings (e.g., paint, powder coatings) can increase the corrosion resistance, aesthetics, and durability of the enclosures.

- Manufacturing Efficiency and Consistency

-

- Automated production equipment:CNC machines and automatic welding robots can improve production efficiency, ensure the stability of each batch of products, and reduce errors and waste in the production process.

- Functionality and Applicability

-

- Precision stamping technology:CNC punch presses can quickly and accurately create functional holes and shapes, such as ventilation holes, mounting holes, and wiring holes, to meet the practical application needs of machine tool enclosures.

- Flexible design and processing:The flexibility of sheet metal technology allows for custom enclosure designs based on the specific requirements of the machine tools, ensuring a perfect match between the enclosures and internal structures and functions.

- Cost Reduction and Environmental Protection

-

- High material utilization:Efficient cutting and stamping techniques can maximize the use of metal sheets, reducing material waste.

- Energy-saving and environmentally friendly technologies:Modern sheet metal technology continuously improves in reducing energy consumption and environmental pollution, contributing to a greener production process.

If you have any sheet metal processing needs for your machines, feel free to contact WeTCC!