Technical Advantages

Technical Advantages

Sheet metal manufacturing equipment includes a range of machines and tools used for cutting, bending, welding, stamping, and other processing operations on metal sheets.

CUTTING EQUIPNENT

Laser Cutting Machine

Uses a high-energy laser beam for precise cutting, suitable for complex shapes with high accuracy.

Plasma Cutting Machine

Utilizes high-temperature plasma to cut, ideal for fast cutting of thick sheets.

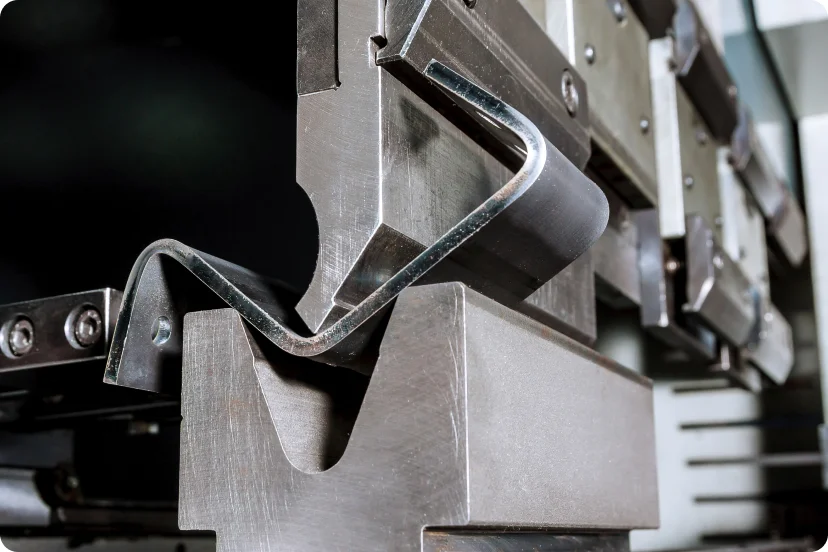

BENDING EQUIPMENT

Press Brake

Used to bend metal sheets into desired angles and shapes, suitable for various angles and complex shapes.

Roll Bending Machine

Bends metal sheets into cylindrical or conical shapes through rolling.

PUNCHING EQUIPMENT

Punch Press

Uses a punch and die to stamp metal sheets into shape, suitable for mass production.

WELDING EQUIPMENT

Robot Welding System

Uses industrial robots for welding operations, suitable for high-efficiency and high-precision welding needs.

Robotic fiber laser welding machine

CO2 robotic arm

These pieces of equipment play a crucial role in modern sheet metal processing, meeting various processing needs and improving production efficiency and product quality

HANDHELD WELDING EQUIPMENT

Robot Welding System

Uses laser light for precise welding, suitable for thin sheets and high-precision welding.

Spot Welding Machine

Used to weld two metal sheets together at a single point.

CO2 welding machine

Utilizes a continuous feed of consumable solid wire (electrode) to create an arc with the base metal, causing the weld pool to melt, and then shields the arc and molten weld pool with a protective CO2 gas.

Electric welding machine

Generates an arc by touching and immediately separating the welding rod and the workpiece base metal, with the high temperature of the arc melting the welding rod and causing it to drop onto the molten base metal.

SURFACE TREATMENT EQUIPMENT

Polishing Machine

Used to polish the metal surface, making it smooth and shiny.